When starting an activity in which a burner is required, the question always arises as to what type of burner will best suit what we need. The first thing we must be clear about is whether we are going to use natural gas or propane, as this will determine the pressure that will reach our installation. If we use natural gas from the municipal network, we will get a pressure of 22 mbar; in industrial estates, pressures of up to 2 bar can be obtained, but not in urban centers. If, on the other hand, we are going to use LPG, we can obtain up to 1.75bar.

Natural gas is already regulated at 22mbar to our company, so it is NECESSARILY to use low pressure burners that we will connect to the network through an approved hose.

The pressure of bottled butane and propane is much higher than that required at the point of consumption; we will need a regulator to reduce the cylinder pressure to that of consumption.

If the burner is low pressure, we will require a 30 / 37gr reducer that we can connect directly to the butane bottle; if, on the other hand, we have a high pressure burner, we must connect a 1.7 bar regulator to the cylinder valve.

To determine the burner we need, the model to choose will depend on the power we require.

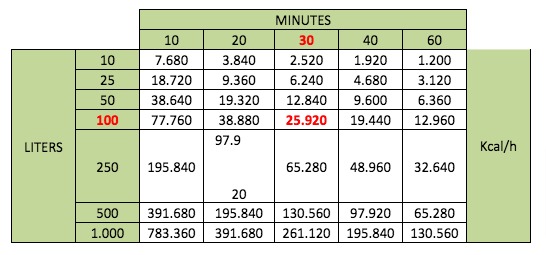

The following table tells us what power we need to raise the temperature of a certain volume of water from 15⁰C to the boiling point depending on the time required.

Example: With a 25,920kcal / h burner, we can bring 100lit to a boil in 30min.

This burner would be for example our 411/6 of 30,000kcal. Other models can be found on the market, such as the QC4, but they do not reach this power.

How to calculate how many bottles we need?

The number of bottles must be adapted to the consumption of the burner. To calculate it, we divide the power in kcal / h by 12 and obtain the amount of gas it consumes:

kcal/h ÷ 12 = kg/h

Taking into account that a propane or butane bottle gasifies a maximum of 1 kg / h at an ambient temperature of 15⁰C, to achieve optimal performance in continuous use and prevent the bottles from freezing, we must join as many bottles as kg / h consumed by the burner . The cylinders can be connected with derivations and gas hoses, but in the case of large consumptions, it is recommended to install a battery of cylinders or a bulk tank.

Safety first. It is essential that the burner incorporates a flame detection system; This can be a thermoelectric safety valve connected to a thermocouple, or an ionization electrode or UV detector connected to an electronic control system.

And don’t forget: Before lighting the burner, always check its tightness using a leak detector spray.