Burning bar

Thermal lance

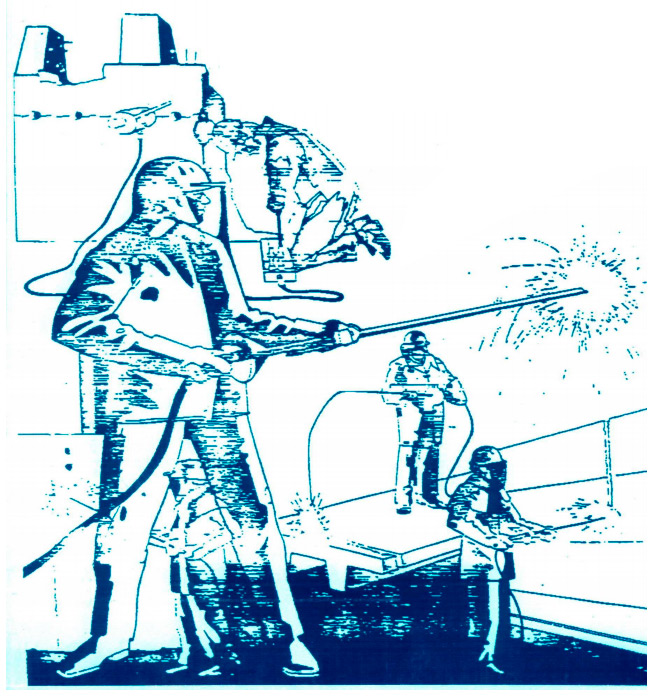

Now you can handle the biggest jobs quickly and

quietly without jackhammer

El sistema Burning Bar corta y funde silenciosamente a través de los más tenaces y espesos aceros, aceros plaqueados en sandwich, inoxidables, fundiciones de hierro, hormigón, granito o incluso aleaciones de plomo tipo kirksite y asbestos o productos y ladrillos refractarios.

BURNING BAR SYSTEM

EXOTERMIC CUTTING SYSTEM ONLY WITH OXYGEN

Description

The Burning Bars are self consuming cutting tools used in a wide variety of industries for cutting most ferrous and nonferrous metals, refractory and concrete.

Benefits over conventional cutting methods are faster cutting speeds and the ability to cut thick sections as well as rusty or corroded materials

WHAT IS THE DIFFERENCE BETWEEN OXY-FUEL AND EXOTHERMIC CUTTING?

The Oxy-Fuel cutting torch uses a preheat flame to elevate the temperature of the material to be cut to 1500 to 1900 degrees F. When the steel becomes cherry red a high pressure jet of

oxygen is directed at the pre-heated metal. The result is the metal is rapidly oxidized or it burns. This process works on material that will oxidize. If it will not rust it can not be readily cut with an oxy-fuel system

The Exothermic process also utilizes oxidation. However; the exothermic process uses alloys in the material in the burning bar as the fuel and produces temperatures of 7200 degrees f.

A Burning Bar consists of an outer steel tube filled with special alloy wire. The exothermic reaction (Oxidation) occurs when the tip of the rod is heated to its kindling temperature (1800 f) and pure oxygen is introduced through the bar. The chemical reaction will continue until the bar is consumed or the oxygen flow is turned off. The only gas required for this cutting operation is pure oxygen. Cutting steel with an exothermic torch requires no preheat or cleaning.

What sizes are available?

Oxylance manufactures a variety of Burning Bars, Sure Cut Rods and Underwater Cutting Rods. 10’6” Burning Bars are available in Pipe and Tube sizes from .540” O.D. up to 1.05” O.D. The smaller Sure Cut Rods are available in Tube sizes of 1/4” and 3/8” O.D. in lengths of 24”, 36” and 48 inches. All tubing is measured by outside diameter and pipe is measured by nominal inside diameter. Oxylance identifies both pipe and tubing by the outside diameter in order to identify the proper holder required for a particular size burning bar.

What is the most important part of the equipment?

Other than proper fire proof clothing and eye protection, the most important parts of the system are the Oxygen Supply, Oxygen Hose and Regulator. For most applications involving the large Burning Bars Oxylance recommends 1/2” hose and a High Flow Regulator with a 1/2” port on the output side. This eliminates the possibility of flow restriction and ensures proper volume of oxygen to the Burning Bar.

What is the most critical part of the process?

The exothermic process relies on OXYGEN VOLUME and PRESSURE. Without proper volume of oxygen the cutting process will not work and creates hazards to the operator. Minimum and maximum volumes and pressures are listed with each size Burning Bar. You MUST supply the minimum volume and pressure for safe efficient operation. For all of the large burning bars you CAN NOT operate them with a single liquid oxygen tank. Please refer to the section on oxygen for proper set up information if liquid Dewars are to be used.

Burning bars are cleaned for oxygen service and must be stored in a manner that prevents them from becoming contaminated by oil, grease or any substance thatwill react with oxygen.

Cutting a turbine shaft 44 “(1.12 meters.) In diameter

Applications

- STEEL MILLS / FOUNDRIES Cleaning up metal spills

- Opening Tap Holes

- Repairing Slag Pots

- Cutting Refractory

- Cutting Skulls

- Cutting Slag

- Processing Scrap

- Ferrous and Non Ferrous Smelters

- POWER PLANTS / REFINERIES Removing Boiler Tubes

- Remove / Replace Precipitators

- Removing frozen pins

- Repair Large Rollers

- Gouging cracks in thick material Cut / Pierce Concrete

- Cut Laminated material

- Cut steel underwater

- EMERGENCY / RESCUE Train derailments

- Breeching Operations

- Cutting Burglar Bars

- Open doors w/ hardened deadbolts

- Cutting collapsed structures

- Cutting Guardrails

- Used by Farm Medic teams

- Military / Police

Temperate cut

You can view and download the information on this page in pdf format by clicking on the button

Do you have any doubt?

If you need help do not hesitate to contact us

Contact us through this contact form. If you prefer in the contact section or footer you can find different ways to answer your questions.